Stainless steel is renowned for its resistance to rust and corrosion, but that doesn’t mean it’s entirely immune. Environmental factors, improper handling, and exposure to corrosive substances can lead to rust formation on stainless steel sheets. For industries relying on this material’s durability, rust prevention is crucial for maintaining quality and performance. In this guide, we’ll cover practical, essential tips for keeping stainless steel sheets in prime condition and how working with trusted stainless steel sheet suppliers can make a significant difference in quality and longevity.

Understanding the Basics of Rust on Stainless Steel Sheets

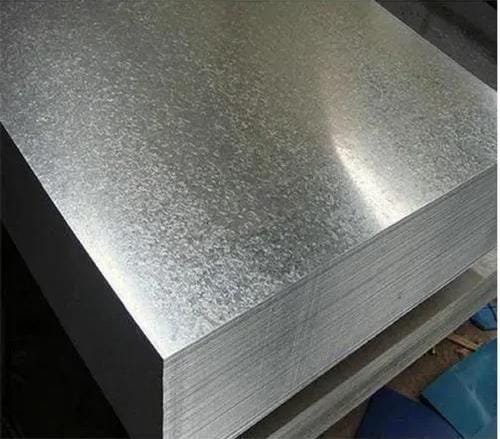

Stainless steel sheets are alloyed with chromium, which gives them their rust-resistant properties. When exposed to oxygen, chromium forms a passive layer of chromium oxide, effectively protecting the steel beneath from corrosion. However, this protective layer can degrade over time, especially if the material is subjected to harsh conditions.

Even with this passive layer, stainless steel sheets are vulnerable if mishandled, scratched, or exposed to contaminants. Knowledgeable stainless steel sheet suppliers understand the risks and ensure high-quality sheets that meet standards for durability.

1. Selecting High-Quality Stainless Steel Sheets

Starting with high-quality stainless steel sheets is the best defense against rust. Sheets with higher chromium content or additional alloys like molybdenum offer greater resistance to corrosion. For instance, grade 316 stainless steel includes molybdenum, which provides extra protection against rust, making it ideal for environments with high moisture or salt exposure.

Partnering with reliable stainless steel sheet suppliers ensures that the material you receive has optimal resistance properties. Quality control, certifications, and material testing are essential elements that suppliers should provide. Investing in top-grade stainless steel at the outset saves time and resources by reducing the likelihood of rust formation over time.

2. Proper Cleaning Techniques for Stainless Steel Sheets

One of the most effective ways to prevent rust is by maintaining clean stainless steel sheets. Cleaning removes potential contaminants that could damage the protective oxide layer. For general cleaning, use warm water and a mild detergent. Avoid abrasive scrubbers, as they can scratch the surface and expose the steel underneath to rust.

For industrial applications, it’s advisable to use specialized stainless steel cleaners recommended by stainless steel sheet suppliers. These cleaners contain protective agents that help maintain the integrity of the oxide layer and can be effective in removing more stubborn residues. Regular cleaning, especially in environments with high exposure to moisture, will significantly prolong the lifespan of the stainless steel.

3. Avoiding Contact with Harsh Chemicals

Chemicals like bleach, chlorine, and muriatic acid can break down the oxide layer on stainless steel sheets, leading to rust formation. Always avoid direct contact with these substances, and if accidental contact occurs, rinse the surface thoroughly with clean water to prevent damage.

If using stainless steel sheets in an industrial setting where exposure to harsh chemicals is inevitable, consult your stainless steel sheet suppliers for information on chemical-resistant grades. They may offer specific grades that are better suited to withstand chemical exposure, such as grades containing higher molybdenum levels.

4. Preventing Cross-Contamination from Other Metals

Cross-contamination is a common cause of rust on stainless steel sheets. Contact with iron or carbon steel particles can transfer contaminants onto the stainless steel surface, creating rust spots. For example, using tools previously used on non-stainless steel metals can transfer particles to the stainless surface.

To minimize this risk, always use dedicated tools and equipment specifically for stainless steel. Stainless steel sheet suppliers recommend keeping stainless steel storage areas free from other metals to reduce the risk of cross-contamination. Additionally, inspect sheets for any foreign particles after handling to maintain a rust-free surface.

5. Proper Storage Practices to Prevent Rust

Storage plays a major role in preventing rust. Stainless steel sheets should be stored in a dry, clean environment, preferably away from direct exposure to weather elements. Moisture, high humidity, and dust can contribute to rust formation, even on stainless steel. It’s also important to avoid wrapping stainless steel in materials that can trap moisture, such as plastic, as this creates a breeding ground for corrosion.

Storing stainless steel sheets with protective coatings or coverings is recommended by most stainless steel sheet suppliers. If the sheets must be stored outdoors or in less-than-ideal conditions, using a breathable cover that allows airflow while protecting against moisture is the best approach.

6. Applying a Protective Coating for Additional Rust Resistance

While stainless steel sheets are naturally rust-resistant, additional coatings provide an extra layer of protection, especially in challenging environments. Common coatings include epoxy or powder coatings, which create a barrier against moisture and contaminants. For applications where aesthetic quality is important, clear coatings preserve the metal’s natural appearance while enhancing rust resistance.

Consulting stainless steel sheet suppliers about recommended coatings for specific applications can provide insight into the most effective solutions. Suppliers often offer pre-coated options or advise on appropriate aftermarket coatings to suit different industrial environments.

7. Regular Inspection and Maintenance of Stainless Steel Sheets

Regular inspections allow for early detection of rust or other forms of corrosion on stainless steel sheets. During inspections, look for any signs of discoloration, dull spots, or surface rust, as these may indicate early corrosion. Addressing minor rust spots with stainless steel cleaners and mild abrasives can prevent them from spreading.

Most stainless steel sheet suppliers advise conducting thorough inspections in environments where the sheets are exposed to harsh conditions. Keeping a record of inspection results helps in assessing the long-term durability of the sheets and allows for timely maintenance.

8. Using Electropolishing for Enhanced Rust Resistance

Electropolishing is a finishing process that can enhance the rust resistance of stainless steel sheets by removing surface impurities and creating a smoother, more resilient finish. The process involves immersing the stainless steel in an electrolyte bath, which removes the outer layer of metal and enhances the chromium-rich surface layer.

For industries requiring maximum rust resistance, electropolished stainless steel sheets offer superior durability. Stainless steel sheet suppliers can provide electropolished options for applications such as medical devices, food processing equipment, and laboratory settings where hygiene and rust resistance are crucial.

9. Collaborating with Trusted Stainless Steel Sheet Suppliers for Longevity

The right stainless steel sheet suppliers provide more than just material; they offer expertise in selecting, handling, and maintaining stainless steel for specific applications. Working with reputable suppliers ensures that the stainless steel meets necessary standards and is suitable for the intended environment.

Suppliers can guide clients in choosing the appropriate grade, surface finish, and any additional treatments for rust resistance. Regular consultation with suppliers allows for ongoing support, ensuring that the stainless steel sheets maintain their integrity over time.

10. Conclusion: Ensuring Rust-Free Stainless Steel Sheets

Preventing rust on stainless steel sheets requires careful consideration of storage, handling, and maintenance practices. Whether through proper cleaning, avoiding cross-contamination, or applying protective coatings, every step taken can contribute to prolonging the lifespan of stainless steel.

Ultimately, choosing high-quality stainless steel sheets from trusted stainless steel sheet suppliers is the foundation for long-lasting performance. By following these essential tips, industries can ensure that their stainless steel remains free from rust and maintains its corrosion resistance, making it a reliable, sustainable choice for years to come.